Contract manufacturing – mechanical processing

We offer you precise and fast contract manufacturing of your components. In particular, we carry out the production of individual parts and small series according to drawings or samples.

Our production spectrum includes TURNING, MILLING, GRINDING and BENDING of ferrous and non-ferrous metals.

Thanks to our machinery, we are able to carry out many types of processing inexpensively and, above all, at short notice. This is particularly advantageous if, in the event of a machine downtime, we have to produce spare parts that are no longer available or not available at short notice.

With the pipe bending machine that you bought last, hydraulic pipes can be bent to exact dimensions. We are able to produce complex shapes in large quantities. At the same time, we press the pipe ends with cutting ring fittings of various sizes.

Contact us – we will send you an offer quickly and easily.

Turning – individual parts and small series

- length: 1000 mm

- diameter: 560 mm

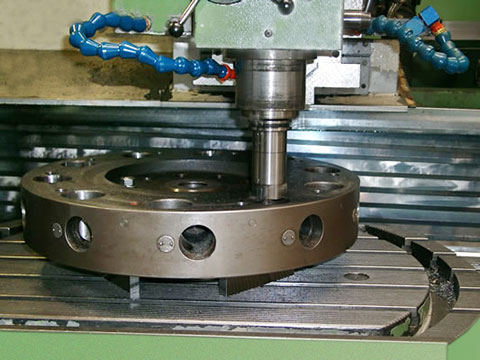

Milling – individual parts and small series

- workpiece weight up to 500 kg

- traverse path X: 900 mm

- traverse paths Y: 520 mm

- traverse paths Z: 450 mm

Grinding – workpieces of the highest precisionn

Plane grinding of surfaces ELB SWBD 15 VA II with new SIEMENS control and angle head.

-

- traverse path X 1.200 mm

- traverse path Y 500 mm

- max. workpiece height H: approx. 300 mm

Pipe bending – bend pipes individually in 3D

With the Turbomat tube bending machine, we are able to bend complex hydraulic lines in series and to provide them with cutting ring screw connections.

We only need a drawing (file format: STEP, IGES) or hand sketch to send you a non-binding offer.

pipe diameter (mm): 8/10/12/15/16/18/20/22

cutting ring fittings: 6L/6S/8S/8L/10L/10S/12L/12S/15L/16S/18L/20S/22L

max. tube length: 3000 mm